HOW-TO

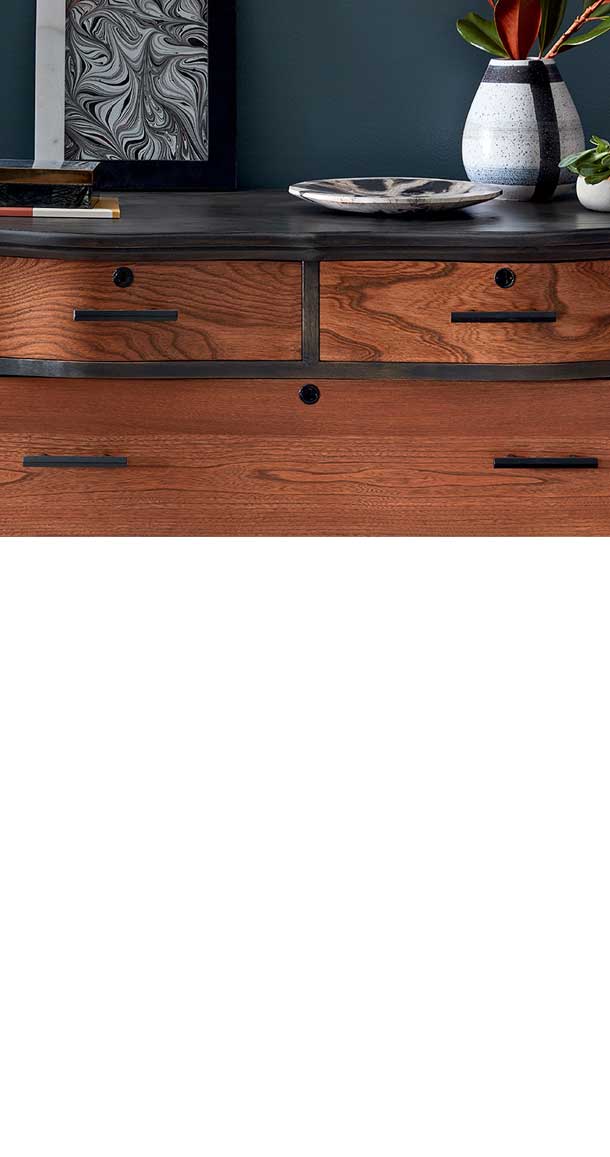

Wood Staining 101

Basic tips and advice on choosing and using wood stains.

HOW-TO

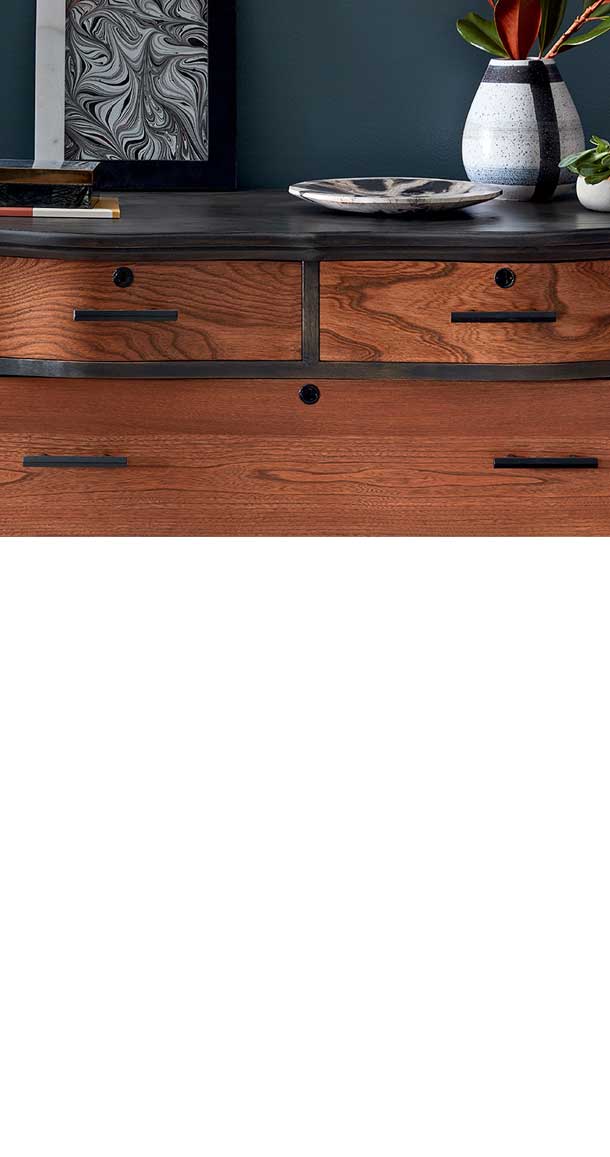

Wood Staining 101

Basic tips and advice on choosing and using wood stains.

HOW-TO

Basic tips and advice on choosing and using wood stains.

HOW-TO

Basic tips and advice on choosing and using wood stains.