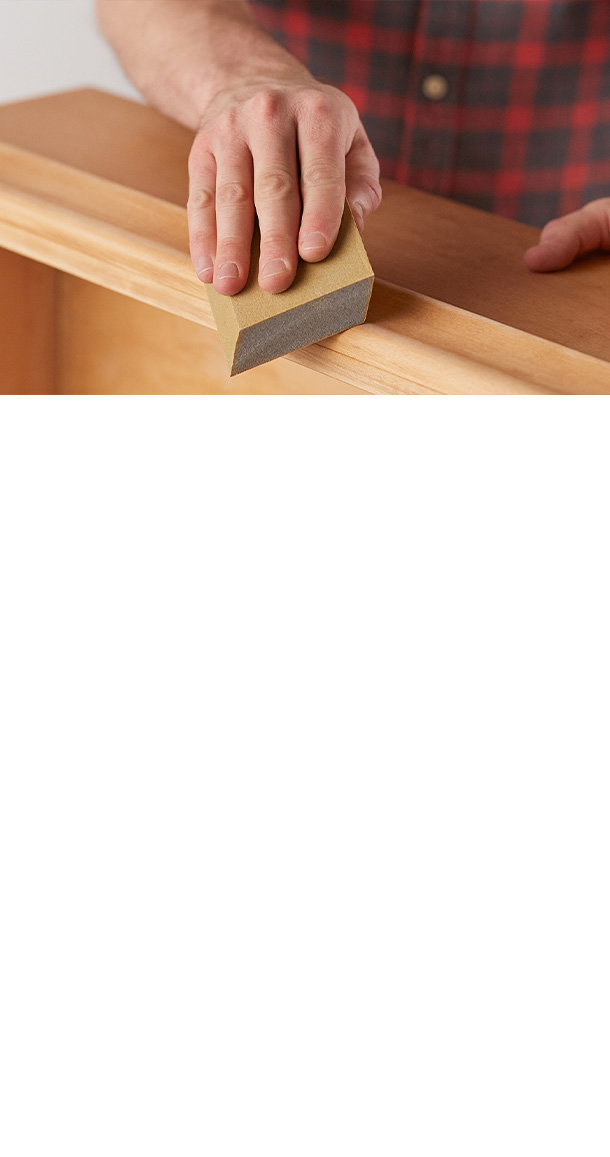

Preparation

The better the wood preparation, the better the end result. Get off to a good start with your wood project.

Preparation

The better the wood preparation, the better the end result. Get off to a good start with your wood project.