HOW-TO

Tips and Pitfalls of Stain Matching

HOW-TO

Tips and Pitfalls of Stain Matching

Wood is unpredictable

Those three words account for the vast majority of the problems we encounter while attempting to change the color of a board using stains. Wood is made up of millions of cells we rely on to absorb pigments and dyes - the absorption rate and capacity of which are affected by an astonishing number of factors - which is why, when it comes to staining, wood is unpredictable.

The Pitfalls: Why is this so difficult?

One of the most common reasons for staining wood, whether it be a piece of unfinished furniture, woodwork, doors, floors, or trim, is to make it match an existing color in that room. Very often, the color is in another piece of wood, but sometimes the inspiration comes from fabric, draperies, upholstery, even artwork.

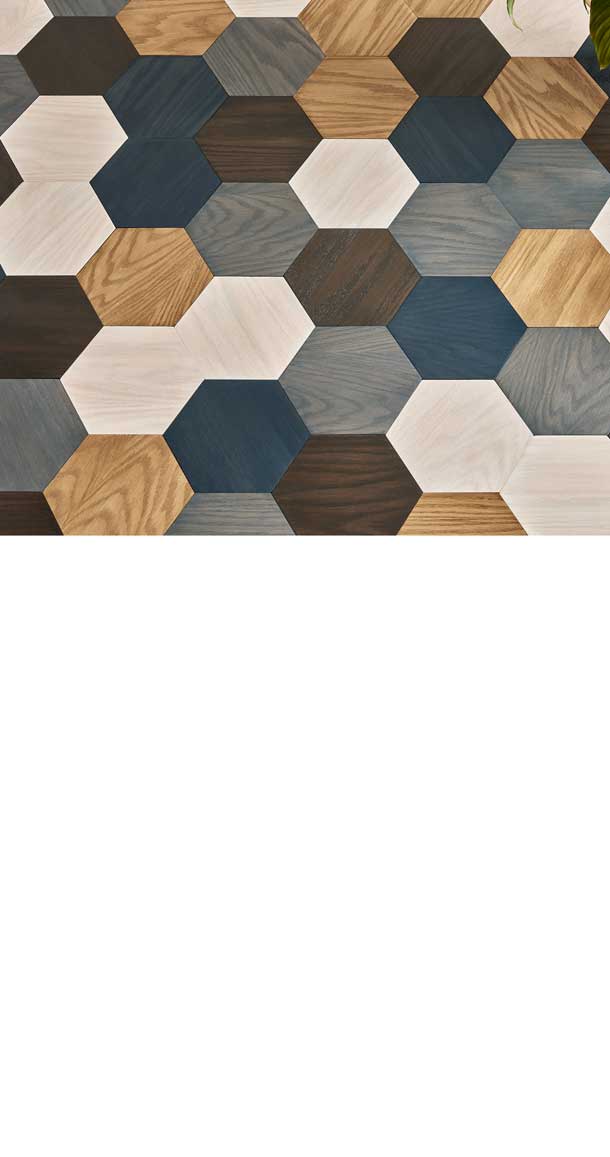

When we are fortunate, the piece of wood we are staining is of the same species as that we are matching, such as when we bring home an unfinished oak dresser to match a finished oak bed. When we are not as fortunate, the piece being brought home is of a different species or, worse yet, consists of more than one species of wood.

Even when the two boards are of the same type, we oftentimes discover that the same stain does not produce the same results. The cells which form the pores of an oak board, for instance, vary in their natural color from red oak, which has a natural pinkish tint, to white oak, which is actually tan. The same is true for the various types of maple, pine and mahogany, just to name a few. Since the Minwax® stains we apply are intended to reveal, not disguise the natural grain of the wood, the inherent color of the pores is going to affect the final color after we have applied our stain.

Grain Patterns

Even when working with two boards of the same type, other factors enter which can complicate the stain matching process. The most prevalent is the grain pattern. In each board the pores arrange themselves in a pattern that remains somewhat consistent from board to board. It is this grain pattern, combined with the natural color of the wood, which enables us to distinguish oak from maple or cherry from mahogany. The grain pattern within each species of wood, however, can still vary. Naturally occurring blemishes explain how 'bird's-eye' maple got its name; the same is true for 'fiddle-back' maple prized by violin makers. 'Burl' walnut, with its swirling grain pattern, comes from the root of the walnut tree and is often reserved for expensive inlay and the dashboards of exotic sports cars.

The grain pattern can also be affected by the way in which the lumber is cut from the log. The most well-known example of this is 'quarter-sawn' oak, which, contrary to what some people believe, is not a different species of oak, but rather is a different means of slicing the log into boards. 'Plain-sawn' oak refers to boards that are simply sliced off the log, resulting in boards with a typical, long wavy grain pattern. When the log is first cut into quarters and then cut at a different angle, the resulting boards have large flakes of grain revealed. While the technical term for boards cut in this manner is quarter-sawn, the dramatic flakes account for its nickname, 'tiger' oak. The differences in grain pattern become even more obvious when a stain is applied, for the dyes and pigments magnify the grain pattern of each board, making it difficult to match two oak boards if each has a different grain pattern.

Humidity Levels

Another factor that influences the final color is the amount of moisture in the cell walls of each pore. Wood which is extremely dry is naturally going to be able to absorb more dyes and pigments than one which has a higher percentage of moisture. Most furniture-grade woods are kiln-dried until the moisture level is stabilized at 6%-8%, but since wood shares many of the same attributes as a dry sponge, that percentage of moisture can change dramatically in direct proportion to the conditions in which it is stored. The age of the wood is yet another determinant we must consider. The most well-known example is American cherry, a wood that has been favored by cabinetmakers and homeowners for centuries. Treasured for its subtle grain pattern and natural reddish hue, cherry begins to change its color on the day it is first cut. You only have to compare a rich, reddish new cherry board to a 150-year-old cherry chest of drawers in a museum or antiques shop to see how dark cherry will turn over time.

All of this is mentioned simply because it is only by removing or reducing the differences in natural color, grain pattern, moisture and age between two boards can we have any hope of achieving a near-perfect stain match.

Will I ever get a good match?

Once we have done all that we can to reduce the differences between the two boards we want to match, we can take additional steps to ensure a close match. The first is to realize that you should not apply any stain to your wood until you have tested it on either scraps of the same wood or in an inconspicuous spot, such as the underside of an unfinished chair seat or portion of flooring which will be covered by the piano. For it to be effective, the test has to take place on the identical -- not just similar -- piece of wood.

When selecting a color of Minwax® stain for your project, bear in mind that the color samples printed on the can or in one of our brochures, or shown in the online stain guide can only be an approximation of the color your board will be. While the photography utilized in reproducing the colors of our stains is of the highest possible quality, wood remains unpredictable. For that reason, I recommend buying two or three of the smallest cans available of the color tones which you are wanting to achieve. Once you determine which stain -- or combination of stains -- provides you with the color you want on your particular board, you can, if necessary, return to the store and buy it in a larger container.

Stain Blending

And speaking of mixing stains, keep in mind that even though Minwax® offers an array of both oil-based and water-based colors, you may find that the perfect color for your project is a blend of two or more colors that you custom mix. You only need to follow three rules: first, never mix oil-based stains with water-based stains; second; measure your ingredients precisely using plastic measuring spoons or cups; and, finally, write down your exact formula so that you can duplicate it the following day or year.

Controlling Stain Intensity

The final color of the board will also be affected by how long you allow the stain to be absorbed by the pores before you wipe off the excess liquid. When you are testing your stain, time various samples and compare the color of that left on for one minute versus that left on for three or five minutes.

Lighting Conditions

One other factor to consider when matching stains is the light under which you are working. Bear in mind that a color viewed under three common yet different lighting conditions, namely natural sunlight, incandescent bulbs and fluorescent tubes, can have three different color tones. The difference may not be immediately obvious, but two colors that seem to match under a fluorescent light in your workshop may not actually match when brought into your dining room. The rule of thumb is simple: apply your stain under the same lighting conditions as the room where the piece will be.

Every little bit helps...

With some of these tips, the differences in color may be subtle. But when it comes to matching stains, subtle differences can mean the difference between a successful matching and one which leaves everyone disappointed. Learning about the qualities of wood, meticulous staining experimentation and some creativity are the keys to success.

People are drawn to kit furniture because of its high quality and excellent value. Compared to the price tag of pieces in furniture stores, the cost of kits look pretty attractive. And today's kits offer both a wide selection of quality woods and an equally broad range of designs, from basic styles to magnificent reproductions.

We all wish that every piece of wood in our home could stay as fresh and beautiful as the day it was first finished, but that simply isn't possible. Each day the wood around us, from floors and woodwork to furniture and fine antiques, is subjected to sunlight, grit, dust, moisture and dry air.